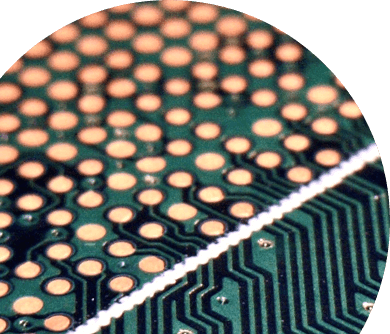

As Odak PCB’s inhouse technology, ENIG (Electroless Nickel Immersion Gold) is a surface finishing technique used in PCB (Printed Circuit Board) manufacturing that provides several significant advantages. One of the main benefits is that it offers excellent electrical conductivity and signal transmission, making it ideal for high-frequency and high-speed applications. Additionally, ENIG provides excellent solderability, ensuring reliable and consistent solder joints during assembly. Another essential benefit of ENIG is its durability and resistance to oxidation, which can prevent the formation of unwanted oxides on the surface of the board. This property, coupled with its relatively flat surface, makes it an excellent choice for surface-mount technology (SMT) components. Overall, ENIG is a crucial surface finishing technique that ensures high-quality, reliable, and long-lasting PCBs that can perform optimally in a wide range of applications.