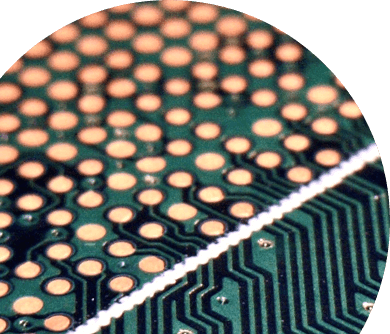

Impedance control in PCBs refers to the process of controlling the electrical impedance of a trace on a printed circuit board (PCB) to a specific value. This is typically done to ensure proper signal integrity in high-speed and/or high-frequency circuits. Impedance control is achieved by adjusting the trace width and spacing, and the dielectric constant of the PCB material. The goal is to match the impedance of the trace to that of the source and load, so that the signal travels with minimal distortion and loss. Impedance control is essential in high-speed digital and RF circuit design, such as in computer buses and wireless communications.

Here are some important points to consider when designing a impedance controlled PCB.

- Understand the requirements: Before starting the design, it's important to understand the specific impedance requirements of the circuit, as well as the operating frequency and signal integrity requirements.

- Use simulation software: Impedance control can be complex, and it's important to use simulation software to analyze and optimize the design before fabrication.

- Control trace width and spacing: The width and spacing of the traces on the PCB can significantly affect the impedance, so it's important to carefully control these parameters.

- Consider the dielectric constant: The dielectric constant of the PCB material can also affect the impedance, so it's important to select a material that has the appropriate value for your application.

- Use controlled impedance traces where necessary: Controlled impedance traces are specially designed trace geometries that are meant to reduce the variability of the impedance. They can be used in digital or high-frequency circuits.

- Test and verify: After fabrication, it's important to test and verify the impedance of the PCB to ensure that it meets the specified requirements.

- Seek Professional Assistance: If you are not familiar with the process of impedance control, it is best to seek professional assistance to ensure that your PCB design is optimized for your specific application.