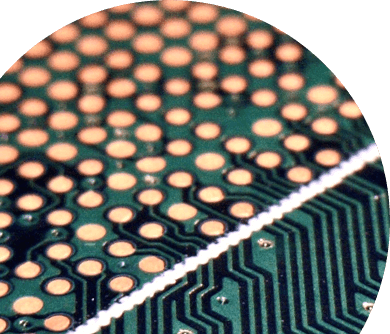

Ionic contamination is the presence of ionized particles on the surface of a Printed Circuit Board (PCB). It can be caused by a variety of sources, including cleaning solutions, flux residues, and humid environments. Ionic contamination is important to consider in the design and manufacture of PCBs because it can negatively impact the performance and reliability of electronic devices.

One of the main concerns with ionic contamination is its effect on soldering. Ionic contamination can cause poor wetting of the solder, resulting in unreliable connections and potential short circuits. This can lead to a higher rate of defects and failures in the finished product.

Ionic contamination can also affect the electrical performance of the PCB. Contamination can cause a buildup of static charge on the PCB surface, which can lead to electrical discharge and damage to sensitive components. Additionally, ionic contamination can cause corrosion of the metal surfaces, leading to increased resistance and decreased performance.

Another concern with ionic contamination is its impact on the longevity of the PCB. Contamination can cause corrosion and oxidation of the metal surfaces, which can lead to increased resistance and decreased performance over time. This can ultimately result in the failure of the electronic device.

In order to prevent ionic contamination and ensure the quality of the PCBs, it is important to use appropriate cleaning solutions and methods, properly flux the PCBs, and store the PCBs in a dry, clean environment. Additionally, regular testing and monitoring of the PCBs can help to identify and address any issues of ionic contamination early on.

In conclusion, Ionic contamination is an important aspect to consider in the design and manufacturing of PCBs. Contamination can negatively impact the performance and reliability of electronic devices by causing poor wetting, static charge, corrosion and oxidation. It is important to use appropriate cleaning solutions and methods, properly flux, and store the PCBs in a dry, clean environment, and regularly test and monitor the PCBs to prevent ionic contamination and ensure the quality of the PCBs.